Our Innovative Process and Technology

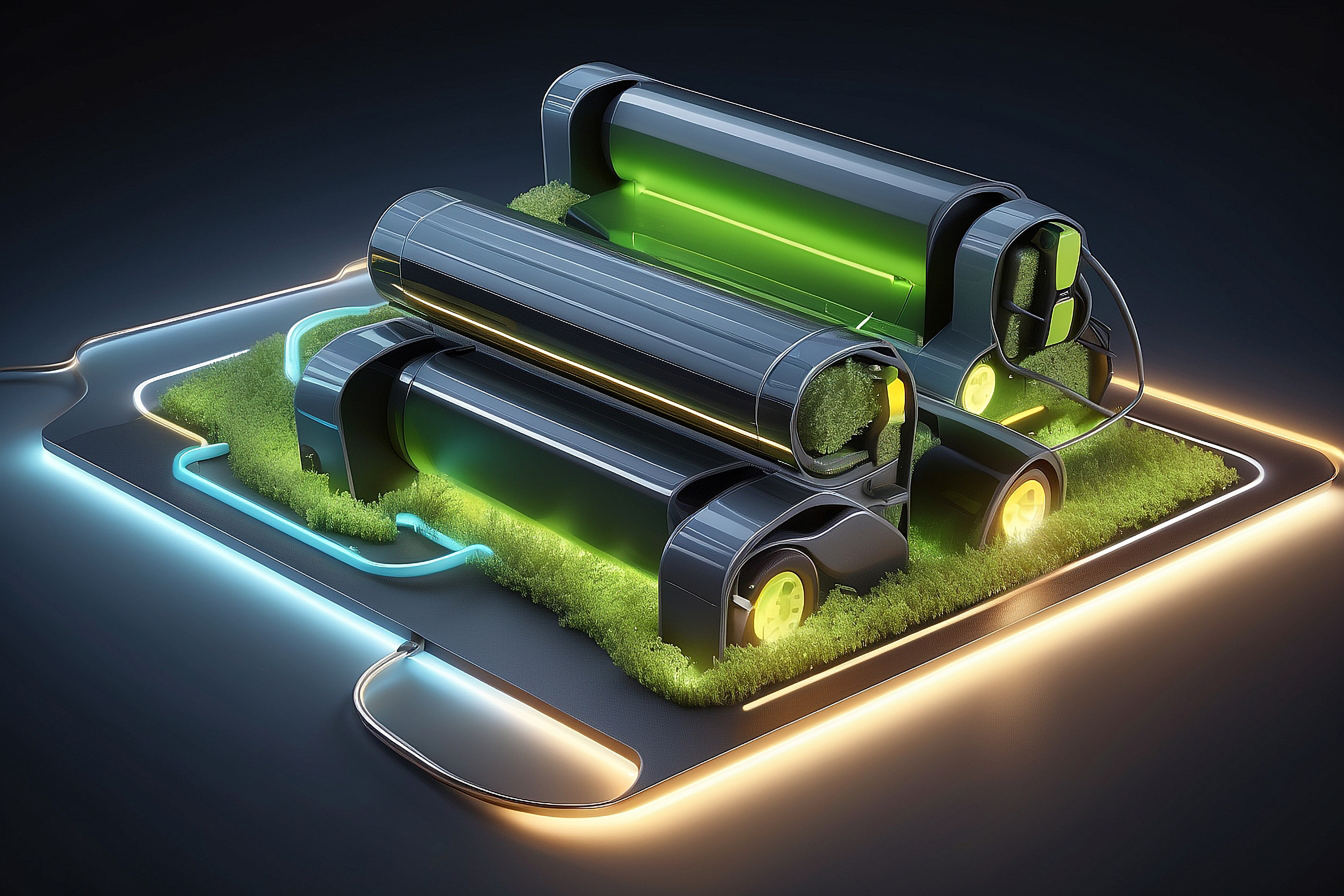

Renewable energy and electric dynamics, lithium-ion batteries have become central to actions in the rapidly changing world. Our company leads the charge, utilizing state-of-the-art technologies to revolutionize lithium battery recycling.