Comprehensive E-Waste & Battery Management Solutions

At METALUX ENERGY LLP provides end-to-end solutions for E-Waste, PCB Waste, Solar Waste, and Battery Waste, including safe collection, professional dismantling, secure data destruction, and eco-friendly recycling. We are committed to reducing environmental impact, recovering valuable resources, and promoting a sustainable circular economy. Our expert team ensures compliance with regulations while helping industries, businesses, and communities manage electronic and solar waste responsibly.

Our Key Sustainability Initiatives

Expanding Recycling Capacity for a Greater Impact

- Current Capacity: 6,000 tons per year of lithium-ion battery recycling.

- 2030 Target: 30,000 tons per year, making us one of the largest battery recyclers in India.

- By scaling operations, we will prevent millions of lithium-ion batteries from ending up in landfills, reducing toxic waste pollution.

Commitment to Carbon Neutrality

- 30% CO₂ Emission Reduction by 2030 – Through process optimization and renewable energy integration.

- Eco-Friendly Logistics & Transportation – Implementing low-emission battery collection and delivery systems.

- Sustainable Recycling Methods – Using energy-efficient material extraction techniques to lower the carbon footprint.

Renewable Energy-Powered Recycling Operations

- Solar-Powered Recycling Facilities – Aiming to run 50% of operations on renewable energy by 2030.

- Energy-Efficient Technology – Upgrading machinery to minimize energy consumption.

Advancing the Circular Economy

- Recovering & Reusing Lithium, Cobalt, and Nickel – Reducing dependency on environmentally harmful mining.

- Supplying Recycled Materials to EV & Energy Storage Industries – Supporting the electric vehicle (EV) revolution.

Regulatory Compliance & Industry Leadership

- Battery Waste Management Rules, 2022 Compliance – Meeting all government regulations.

- Strategic Industry Collaborations – Partnering with EV manufacturers and government agencies.

Collection & Transportation

- Metalux Energy has a robust collection and logistics network enabling waste collection from across the country. We partner with local aggregators, Organization, Private entities and Government Sectors to collect recyclable materials such as electronic waste. Our team works closely with scrap producers to schedule pickups and ensure that all materials are collected in a timely manner.

- Once collected, we transport the waste materials to our recycling facilities using specialized vehicles equipped to handle different types of waste. we handle every step of the process with care, from convenient collection points to eco-friendly transportation methods. Trust us to safeguard the environment while efficiently managing your electronic waste.

Dismantling E-Waste

- Our dismantling services are designed to ensure the safe and efficient extraction of valuable materials from electronic devices while minimizing environmental impact. Our dismantling services are designed to ensure the safe and efficient extraction of valuable materials from electronic devices while minimizing environmental impact.

- We prioritize environmental sustainability in our dismantling processes. By carefully separating and sorting e-waste components, we maximize the recovery of valuable materials such as metals, plastics, and rare earth elements, while minimizing waste sent to landfills. Our dismantling operations comply with all relevant regulations and safety standards. We adhere to proper handling procedures to mitigate potential risks associated with hazardous materials commonly found in e-waste, ensuring the safety of our team and the environment.

Data Distruction

- Reart understand the importance of protecting sensitive data from unauthorized access. Our secure data destruction services utilize industry-leading techniques to irreversibly erase data from electronic devices, including computers, hard drives, and other storage media. Our data destruction processes comply with relevant privacy regulations and industry standards.

- We offer customizable data destruction solutions tailored to the specific needs of our clients. Whether you require on-site data destruction or off-site services at our secure facility, we can accommodate your requirements with efficiency and professionalism. By doing so, we provide you with the ultimate peace of mind, eliminating concerns related to data security, data leakage, and compliance with data protection regulations.

Recycle E-Waste

- We specialize in environmentally responsible disposal and recycling of electronic waste helping individuals and businesses manage their electronic materials sustainably. we offer comprehensive e-waste recycling services for a wide range of electronic devices, including computers, laptops, smartphones, tablets, printers, and more. Our goal is to divert e-waste from landfills and promote the reuse and recycling of valuable materials.

- Our methods comply with industry regulations and standards to safeguard data privacy. Our goal is to divert e-waste from landfills and promote the reuse and recycling of valuable materials. We actively engage with the community to raise awareness about the importance of e-waste recycling.

Our Vision

"At Metalux Energy LLP, we are building a

sustainable, scalable, and carbon-neutral battery recycling industry.

By increasing our capacity to 30,000 tons annually by 2030,

we aim to drive India’s transition toward clean energy and responsible

resource management."

Metalux Energy's Advanced Lithium-Ion Battery Recycling Technology

At METALUX ENERGY LLP, we use a combination of **Mechanical Processing** and **Hydrometallurgy** to efficiently recycle lithium-ion batteries. Our 6,000-ton annual capacity will scale up to 30,000 tons by 2030, making us a key player in India's battery waste management sector.

Step 1: Battery Collection & Pre-Treatment

- Battery Collection – From EVs, electronics, and industries.

- Sorting Process – Based on chemistry and charge.

- Pre-Treatment – Deep discharge for safety.

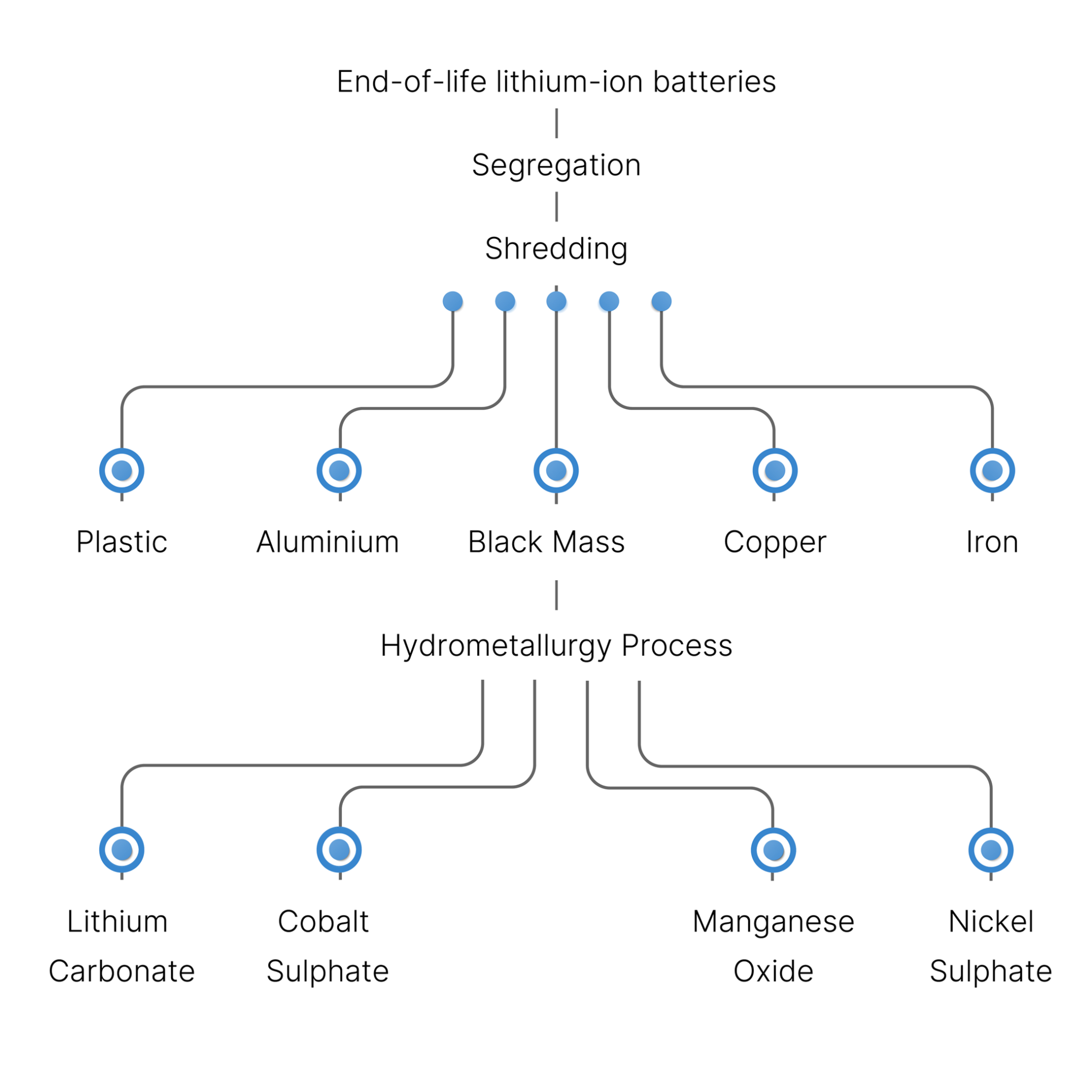

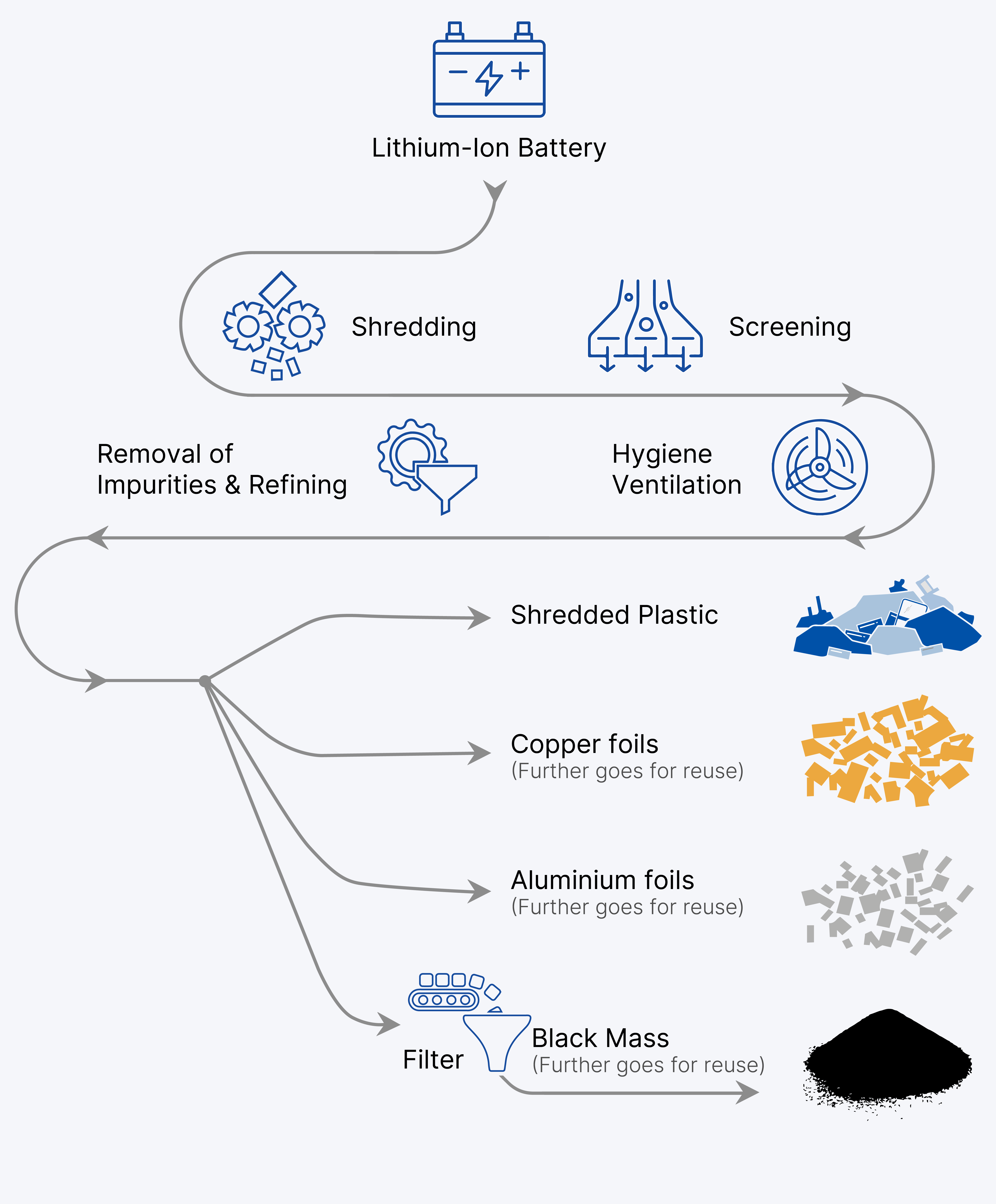

Step 2: Mechanical Processing

- Shredding Process – Breaking down batteries into smaller parts.

- Physical Separation – Using sieving, density & magnetic separation:

- Aluminum & Copper – For manufacturing reuse.

- Plastic Components – Recycled into raw materials.

- Black Mass – Sent for hydrometallurgy.

Step 3: Hydrometallurgical Process

- Leaching Process – Extracting lithium, cobalt, nickel & manganese.

- Purification & Precipitation – Recovery of:

- Lithium Hydroxide – Used for new batteries.

- Cobalt & Nickel Sulfates – Essential for EV batteries.

- Manganese Oxide – For industrial use.

- High Recovery Efficiency – 95%+ material recovery with minimal waste.

Step 4: Zero-Waste Disposal & Circular Economy

- Eco-Friendly Waste Disposal – Ensuring compliance with regulations.

- Material Reuse – Recovered materials supplied back to battery manufacturers.

- Closing the Loop – Supporting a sustainable circular economy.

Why is Metalux Energy’s Technology Superior?

High Recovery Efficiency

Our combined Mechanical + Hydrometallurgy process enables 95%+ metal recovery.

Environmentally Friendly

Hydrometallurgical processing minimizes toxic emissions compared to pyrometallurgy.

Zero Waste Approach

Every component of the battery is either recycled or safely disposed of.

Scalable & Future-Ready

Our process is designed to handle increasing battery waste as India’s EV industry grows.

Powering a Sustainable Future

At Metalux Energy LLP, we leverage cutting-edge technology to recycle lithium-ion batteries efficiently and responsibly. Our Mechanical + Hydrometallurgical process ensures maximum material recovery while supporting India’s transition to clean energy.

Our Recycling Process: Mechanical + Hydrometallurgy

Discharge & Demolition

Safely removes energy, isolates key components.

➜

Material Separation

Crushing & sieving for active material recovery.

➜

Chemical Processing

Leaching out valuable metals with zero waste.

➜

Material Refinement

Purified metals meet battery-grade standards.

➜

New Parts Production

Recycled materials fuel new battery manufacturing.

Key Government Schemes and Policies

+

FAME India Scheme (Phase II)

While primarily focused on accelerating EV adoption, it indirectly supports recycling by encouraging the development of a robust EV ecosystem. Recycling infrastructure is expected to grow as EV penetration increases.

+

Production Linked Incentive (PLI) Scheme for ACC

- Allocates ₹18,100 crore to boost domestic battery manufacturing, including incentives for recycling infrastructure.

- Aims to achieve 50 GWh of ACC battery manufacturing capacity, fostering a sustainable supply chain using recycled materials.

+

Battery Waste Management Rules (2023)

- Mandates Extended Producer Responsibility (EPR), requiring manufacturers to collect and recycle used batteries.

- Sets recycling efficiency targets and prohibits hazardous landfill disposal.

- Formalizes collection networks via battery exchange programs and dedicated centers.

+

NITI Aayog’s National Mission on Battery Storage

Emphasizes creating a circular economy for batteries, including recycling frameworks and partnerships with private players.

+

E-Waste Management Rules (2022 Amendments)

Now includes Li-ion batteries under regulated waste categories, enforcing safe handling and recycling practices.

Research & Development (R&D)

Department of Science and Technology (DST)

Funds projects on eco-friendly recycling technologies.

CSIR Labs and IITs

Researching cost-effective methods for metal recovery (e.g., lithium, cobalt).

Global Collaborations

Partnerships with countries like Japan and Germany to adopt advanced recycling technologies.

Environmental and Economic Benefits

Implementing environmentally friendly recycling for lithium batteries has many environmental and economic benefits:

Resource Conservation:

Recycling conserves the demand for new mined materials, saving natural resources and reducing the environmental degradation linked to mining processes.

Energy Savings:

Recycling battery resources tends to require less energy than extracting and processing virgin resources, resulting in reduced greenhouse gas emissions.

Economic Opportunities:

The recycling business generates employment and leads to economic growth. With the growth in demand for secondary materials recovered through recycling, new business ventures arise in collection, processing, and manufacturing industries.

Challenges and Future Outlook

There are still several challenges in recycling lithium batteries despite the progress:

Collection Infrastructure

Setting up effective collection structures for end-of-life batteries is essential for providing a reliable supply of materials for recycling plants.

Technological Limitations

Certain recycling procedures remain in their infancy and need more research to become more efficient and cost-saving.

Sustainable Lithium Battery Recycling Practices

Synchronizing laws across countries can make the transportation and treatment of battery waste more globalized, leading to an integrated recycling industry.